1.Accumulator are compound in the main body which can avoid the explosive fissile convergence line which is result from parision combined in the material- storage-on-top accumulator;

2.The new platform design for the die head, the lifting platform and head rising separated from each other, not only making the rise of the die head more e stable, but also the die head can move forwards and backwards.

3.According to the double pump, proportion flow valve, the power consumption n can be decrease;

4.Automatic lubrication system;

5.It also has down blow pin, down widen device, double clamping and robot h and;

6.It could be optional configured with tele maintenance system;

7. No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

8. Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

9. Strong clamping force with high pressure and double crank links to lock the mold.

10. Two ways of operating: automatic and manual.

11. Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

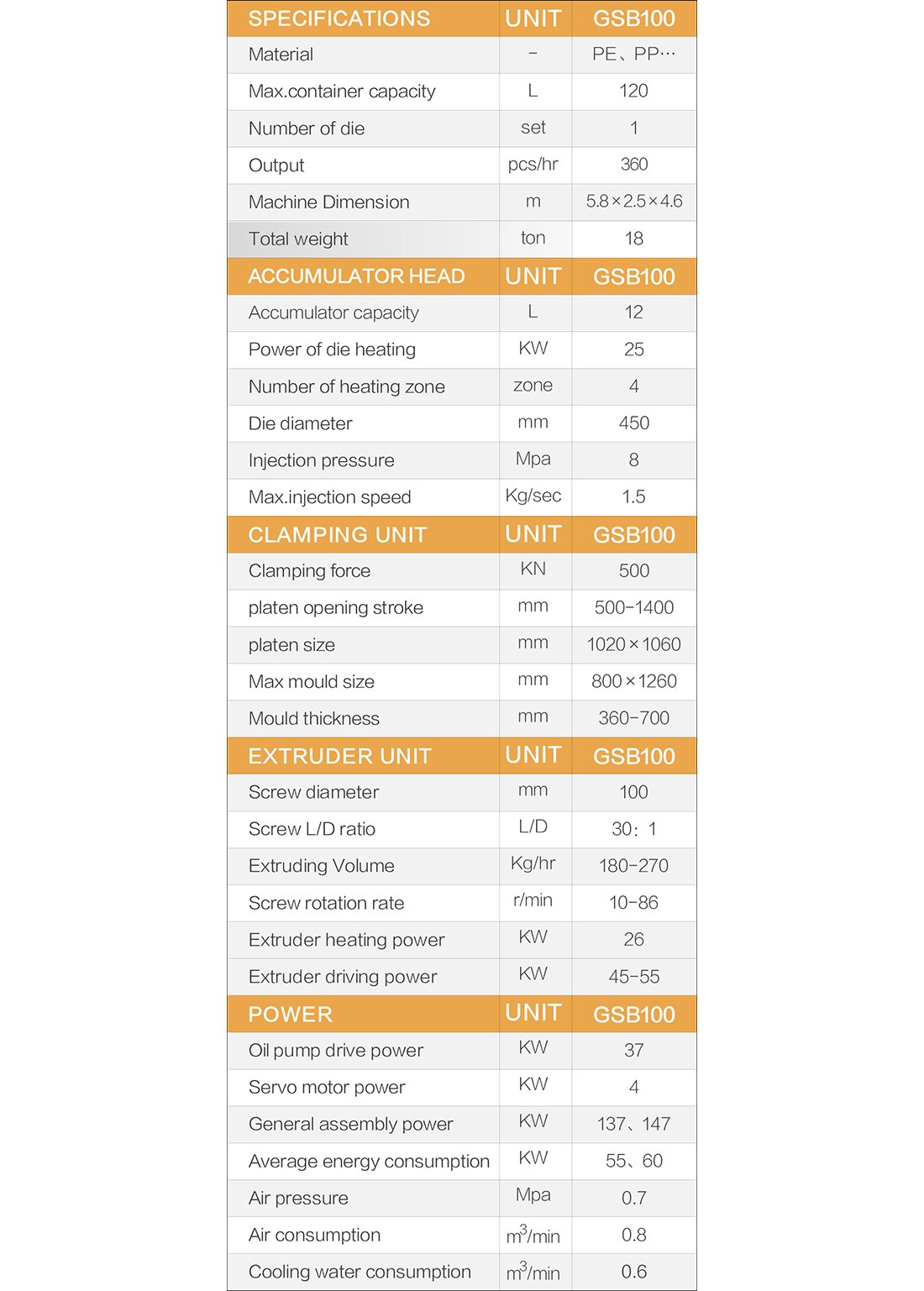

12.The screw diameter is 100mm;

13.The maximum blow volume is 120L,PE、PP can be used, suitable for production of chemical barrels、auto parts and sprayer etc.

GSB100 can produce various plastic components widely used in industry, agriculture, military, etc., including package for chemicals, foodstuff, paints and medicines, plastic tool box, oil tank, hollow parts of car, interceptor, hollow seat, table-top, big extruded toy, pontoon, plate, and big extruded pipe. With the output reaching 30—40 BPH, this machine is especially for items max 120Liter with PP and PE material.

Its control system adopts closed loop control imported from Europe and hydraulic system is pressure-flow double proportional control equipped with variable plunger pump to ensure fast and smooth operation of the machine and energy consumption of the hydraulic system can be reduced by 30% or above, saving considerable electricity.