1. maximum blow volume is 3L, PE, PP, etc. can be used.

2. Different screws and die mandrels, channel styles will be designed based on the specifics of different plastics;

4, convenience to refueling, change color, purge, disassembly and cleaning with those die head. Symmetry part of the wall thickness is very uniform;

5, Double proportional valve control oil flow and pressure, directional valve control flow way, deceleration valve brakes, achieve smooth and fast action;

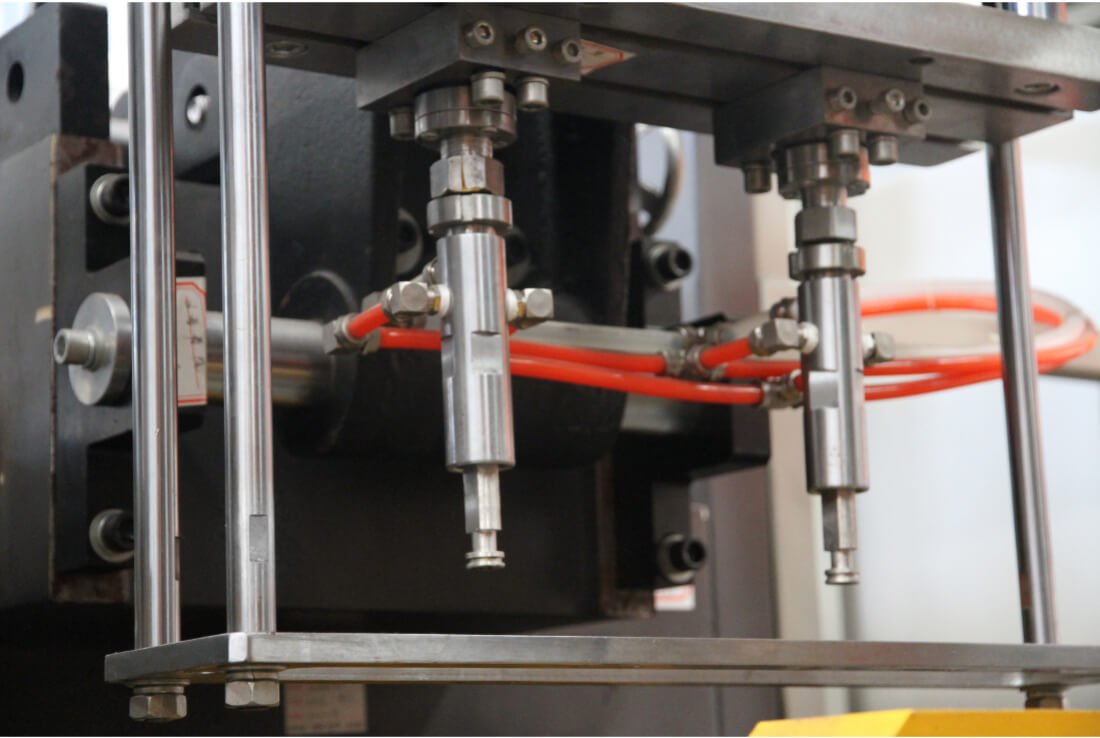

6, Clamping mold is achieved with scissor toggle mechanism, mold carriage is with high-precision ball linear guide, every part of template bears the similar clamping force,

7, Extruder platform can be lifted, easy to adjust the parison length

8. can blow vertically and even blow from certain angle

8, Design is based at CE safety standard, concerning about user safety;

9, Inverter is from France Schneider, adjust the screw speed, saving energy;

10, automatic lubrication system, automatic alarm function, more concerned about the user;

11, Equipped with high temperature alarm function.

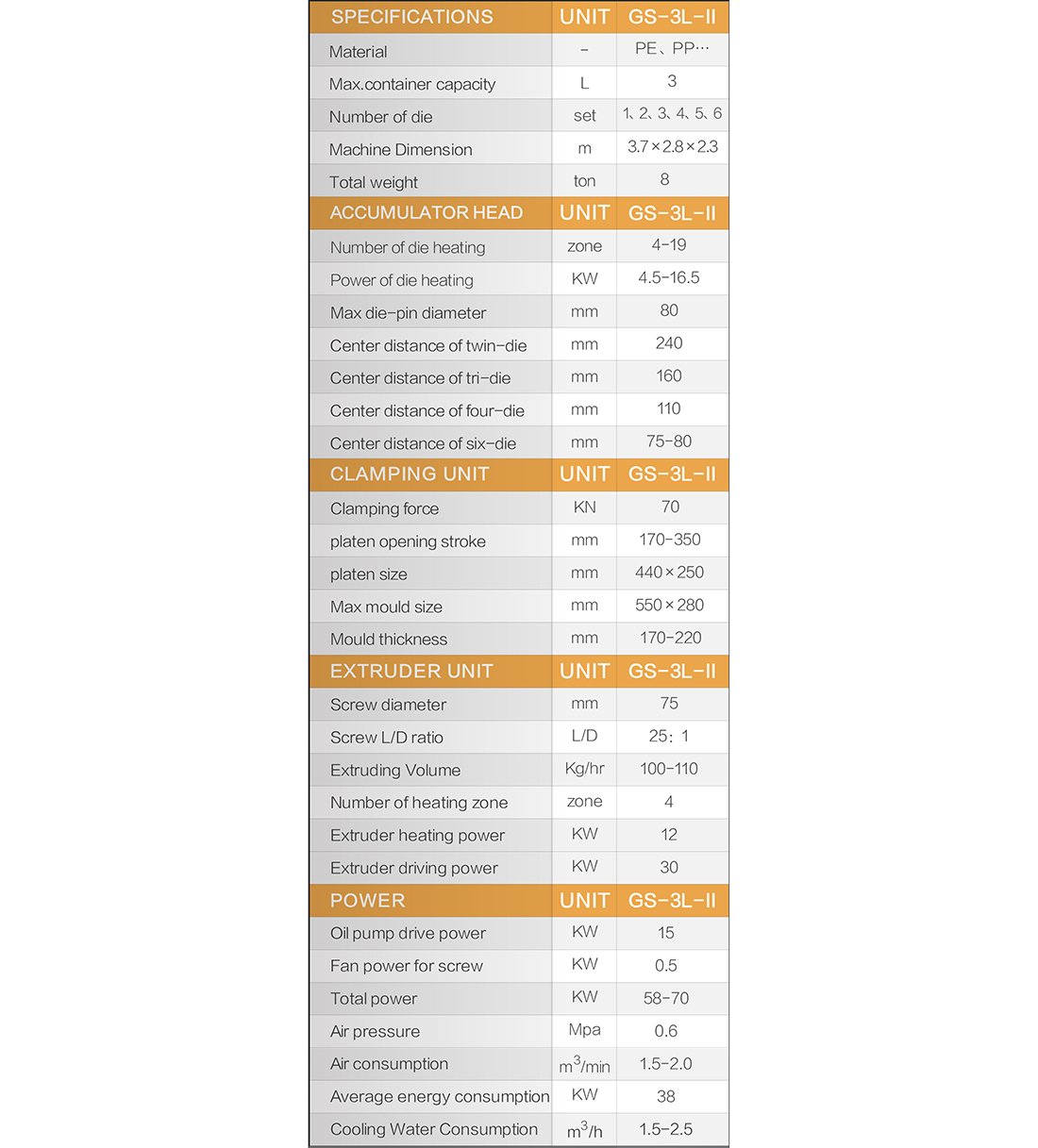

GS-3L-II double station blow molding machine is with 70mm screw, which is used to produce a wide variety of materials, such as PE, PP, etc. This model is specially for bottles 10ml-1L in multi-head, for high-speed use.

This machine is suitable for the small bottles from 30ml upto 1000ml bottles with higher capacity production. In this machine, you can have the options on double station, twin head, triple head, four head and six head. The central distance of six heads is 75mm and four heads is 110mm. many customers run it to make milk bottle, juice bottle. And this is very popular in the beverage filed.

1. Economical equipment, cost is not high, suitable for investment not much and initial industry customers.

2. Dual protection of unique locking frame: first, the guide rail has the valve value electronic components, and the second is that the mechanical limit block is provided at the end of the guide rail to prevent the lock arm from falling off.

3. Inside of the fine machining die, the flow path is free of dead Angle, and professional analysis software is used to measure the smoothness of the runner’s runner, ensuring the smooth and fine flow of the two walls.

4. Optimize hydraulic oil circuit design, save electricity, quick action, convenient parameter adjustment.

5. Variable frequency speed adjustable extrusion motor can adapt to the change of screw rotation speed of blow molding process.

6. According to the product characteristics, different mould heads are set up for customer selection.

7. The oil cylinder structure of the back plate, and the locking force is strong and even.