1, Maximum blow volume is 5L, PE, PP, etc. can be used.

2, Different screws and die mandrels, channel styles will be designed based on the specifics of different plastics;

4, convenience to refueling, change color, purge, disassembly and cleaning with those die head. Symmetry part of the wall thickness is very uniform;

5, Double proportional valve control oil flow and pressure, directional valve control flow way, deceleration valve brakes, achieve smooth and fast action;

6, Clamping mold is achieved with scissor toggle mechanism, mold carriage is with high-precision ball linear guide, every part of template bears the similar clamping force,

7, Extruder platform can be lifted, easy to adjust the parison length

8. can blow vertically and even blow from certain angle

8, Design is based at CE safety standard, concerning about user safety;

9, Inverter is from France Schneider, adjust the screw speed, saving energy;

10, automatic lubrication system, automatic alarm function, more concerned about the user;

11, Equipped with high temperature alarm function.

Suitable for producing high quality container with medium output with from one to four die head, for use in the packaging of petroleum, cosmetics, chemicals, pharmaceuticals, food, toys and auto-parts.

1. Toggle-balanced clamping frame, with well-known liner guide rail from Taiwan; great clamping force and explosion-proof;

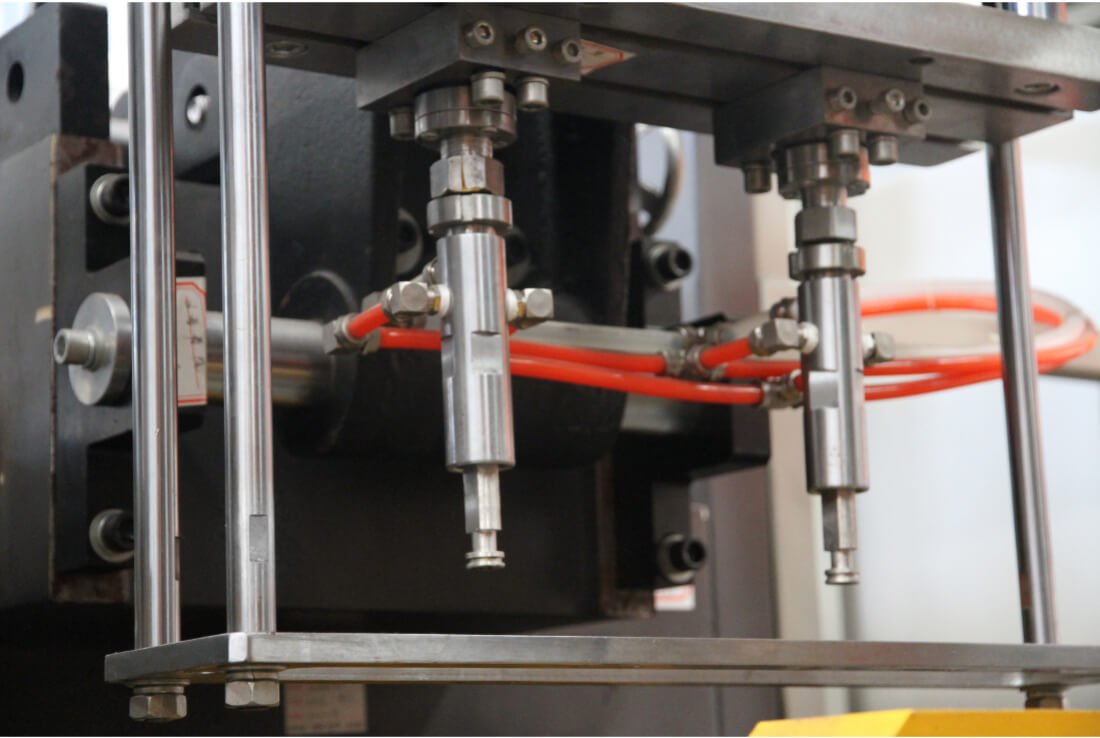

2. Can be achieved multi blow pins at the same time perpendicular to the mold pin blow hole; patented die head, easy for changing color.

3. Computer intelligent control system, operation, set and modify the production process conveniently

4. Deep mirror treatment is used inside die head, curve flow channels are smooth, no dead ends, no carbon left;

5. Strengthened and hardened cold treated screws, screw and barrel are with wear resistance; parts of tube wall thickness are very uniform

6. Various components are produced with Japan’s CNC machine tools, use Mazak to process six-sided installation surfaces at the same time. Imported well-known brands Hydraulic, pneumatic and electrical parts are equipped to ensure that the rigorous process, stable and reliable quality.

7. Machine is with auto de-flashing.

8. can be connected to conveyor to carry waste to crusher to be reused.

9. can be connected to conveyor to carry out bottle and connects filling machine or bottle bagging machine directly.

10. can be equipped with robot arm to take out the bottle.

11. can be equipped with rotary cutter to trimmer foil-sealing bottle